Automatic Cupping and Earing Measurement

Aluminium (aluminum) cans are formed using a drawing and ironing process, leaving cans with a wavy top, otherwise known as ears; with the ears being trimmed and discarded, during the manufacturing process.

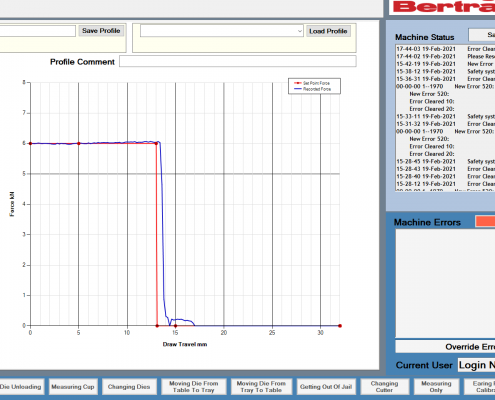

To reduce wastage and cost, aluminium (aluminum) sheet manufacturers determine the quality of the rolled aluminium (aluminum), through an earing test, which measures the peak and troughs of the formed cup to determine how the sheet metal will perform during the next phase of the can manufacturing process.

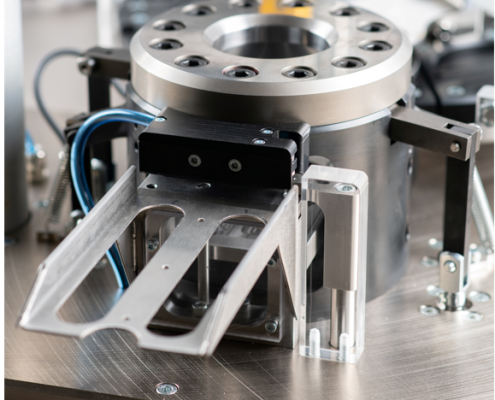

Huxley Bertram designs and builds machines that automate the process of cup forming and earing measurement; with the ability to measure aluminium (aluminum) sheet metal thickness of 0.1mm to 4mm.

Dies are automatically loaded and once formed, cup sample testing takes less than 20 seconds to complete, with the results recorded in supporting analysis software, and conform to both EN 1669 and ISO 11531 standards.

Huxley Bertram also provides a Manual Earing Measurement system.