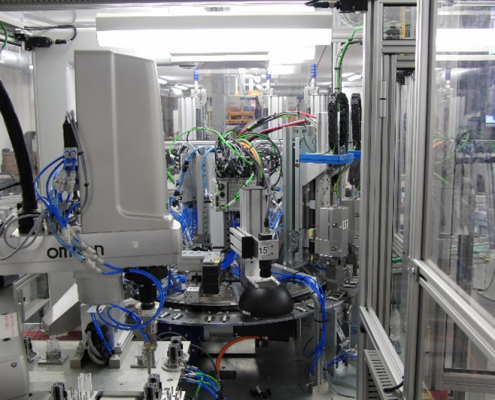

Pick and Place Assembly with Robotic Handling

This special purpose machine is a pick and place assembly system with robotic product load and handling. The production system, automates the assembly of 3 individual parts, (plastics mouldings and metal components) into a final cartridge. Offering a production rate of 60 finished cartridges per minute, the machine operates at a >99% good part efficiency.

The assembly parts are bulk loaded into individual hoppers, which feed into vibratory bowl feeders. Two input conveyors transfer the parts, where a pick and place module loads the plastic components into the 20 station indexing table. An optical sensor detects the presence of the parts and the rotary table indexes for placement of the metal components, a second optical check confirms the correct placement. The final component is loaded by vacuum pick and place and a final optical check is performed.

Capabilities

- 20 million cartridges produced per year

- 20°- 22° angle positioning of metal components

- Protrusion tollerances to 30/40 microns

- 2 second machine cycle rate

- Rejection rate of <1%

- Performace data via HMI