CMAC Open Day, Showcasing Tablet Compaction Simulation

/in #ALL, #News, #Tablet Compaction Simulator /by adminCMAC Open Day – Save The Date

This year’s live CMAC Open Day will be held between, 16th and 18th May 2022 at CMAC’s Technology & Innovation Centre in Scotland. CMAC is the world-leading centre for medicines manufacturing research, skills technology, and translation.

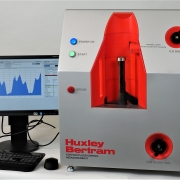

As a CMAC industry partner, Huxley Bertram will be showcasing its Tablet Compaction Simulator range. Delegates who sign up for CMAC’s open day and laboratory tours will be offered a live demonstration of the Huxley Bertram HB50, the high-speed, automated tablet press simulator.

Come and speak with one of our team about how we can support your drug discovery program and reduce time to market; learn more about the full range of Tablet Compaction Simulators offered, including OEB5 containment options, and the extensive tooling and accessories available, such as the adhesion punch, heated tooling, and tri-axial decompression options.

Register Here for this exciting event.

Cambridge LaunchPad

/in #ALL, #News /by adminHuxley Bertram proudly support the Cambridge LaunchPad initiative

The Cambridge LaunchPad programme is an initiative to inspire young students into STEM careers, supported by local engineering and technology companies.

As an industry partner of Cambridge LaunchPad, three of Huxley Bertram’s Junior Engineers engaged with 260 Year 10 students in Cambridgeshire over two days, sharing their knowledge and enthusiasm for engineering. The sessions were delivered through the format of collaborative classroom experiments and live online sessions. Providing real-world engineering examples.

Based on a Huxley Bertram design, the engineers developed an interesting classroom experiment, to mimic a test rig for shock absorption and penetration testing of safety hardhats, through a drop test from height.

Using everyday household items such as playdoh, a rolling pin, golf ball, and a ruler, students measured the drop effect from multiple heights to the playdoh billet. The results were plotted in a graph to prove the theory that drop height influences kinetic energy and force. The students responded enthusiastically, commenting “I like doing DT and I might do engineering now” and “I really like it because it wasn’t like doing normal physics.”

Steve Hales Business Director for Huxley Bertram said: “It has been great for Huxley Bertram to work with Form For the Future. We are immensely proud of our engineering team in both developing and delivering the Cambridge LaunchPad sessions, helping to inspire Year 10 pupils, and highlighting the career opportunities available in an engineering environment.”

Lisa Taylor LaunchPad Programme Manager said: “Thank you to the Huxley Bertram team for delivering engaging content and sessions to our students, providing real-life interactive engineering examples, that will inspire future generations into STEM careers.”

In addition to supporting Cambridge LaunchPad, Huxley Bertram also welcomes applications for Year 10 work placements and student internships for 2023.

Huxley Bertram Shipping Another HB100 – with Containment, Tablet Compaction Simulator

/in #ALL, #News, #Tablet Compaction Simulator /by adminIf you would like more information please get in touch with us at – info@huxleybertram.com

New Contactless Earing Measurement Brochure Completed

/in #ALL, #Earing Measurement, #News /by adminHuxley Bertram have released a new brochure detailing the next generation in Earing Measurement, a Contactless Earing Measurement Machine.

Compliant to EN 1669 and ISO 11531, the CEMU diagnosis Can forming problems in seconds. By utilizing laser technology the machine enables high speed earing measurement, analysis and results. With the capability of measuring Cans or cups from 33mm to 100mm in diameter and 15mm to 200mm in height.

Key advantages of the Contactless Earing Meaurement Unit

- Rapid precision Earing Measurement

- Automatic Grain Detection

- Cup size flexibility

- Advanced Earing analysis software

In addition to the base CEMU, the unit can be fitted with wall thickness measurement and back end/lid scan functionality. By measuring wall thickness, you can identify punch issues during the can drawing process, lubricant application issues or tool wear issues. 3D polar visualisation of the back end of the can or lids allows measurement of curl height, overall height, curl radius, panel depth, inner diameter, out diameter, curl opening and countersink depth.

Want to learn more ? download the Contactless Earing Measurement brochure, by following the link below.

Contactless Earing Measurement Brochure

Project Manager

/in #ALL, #News /by adminHuxley Bertram has a Project Manager vacancy, please visit our careers page for more information.

Sales, Marketing and Business Support Executive

/in #ALL, #News /by adminHuxley Bertram has a Sales, Marketing and Business Support Executive vacancy, please visit our careers page for more information.

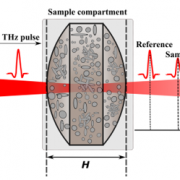

WHITE PAPER – Fast and Non-Destructive Prediction of Tablet Dissolution by Terahertz Spectroscopy

/in #ALL, #News, #Tablet Compaction Simulator /by adminEngineering Apprentice Vacancy

/in #ALL, #News /by adminHuxley Bertram has an Electrical Engineering Apprentice, vacancy, please visit our careers page for more information.

Huxley Bertram and Oxdevice, have produced a ventilator for overseas requirements.

/in #ALL, #News /by admin

+44 (0)1223 203160

Huxley Bertram Engineering Ltd.

53 Pembroke Avenue

Waterbeach

Cambridge

CB25 9QP

England