Automatic Cupping & Earing Measurement Unit featured in Aluminium International Today Publication

Automatic Cupping & Earing Measurement featured in Aluminium International Today

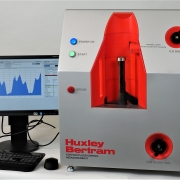

Huxley Bertram’s Automatic Cupping & Earing Measurement unit is featured in the November/December 2022 issue of Aluminium International Today. Aluminium International Today is a print and digital journal focused on the production and processing of Aluminium.

Click the link below to read the full article:

Rapid, accurate, repeatable earing measurement

“The above sounds implausible for many people involved in Earing measurement, but Huxley Bertram’s Earing measurement expertise and equipment are making this a reality.”

Innovating in the field of Earing measurement. Huxley Bertram provide two earing measurement solutions to aluminium rolling mills, Can Body stock manufactures and organisations involved in aluminium research and development.

The ACEM automates the cup forming and earing measurement process. Data is automatically uploaded to a data warehouse for batch release of aluminium coils. Additionally, the ACEM can be fitted with an automatic lubrication system to apply an exact sample dosage, and a rack in-feed system, for up to 50 aluminium sheet samples.

The Contactless Earring Measurement Unit utilizes laser technology to measure pre-formed aluminium cans, of varied height and width. The CEMU diagnoses Can forming problems in seconds.